Supply Chain Risk Management is a area that has seen a significant growth in recent years. However, there is diverse perception of research in supply chain risk because these researchers have approached this area from different domains. A recent article on Researchers’ Perspectives on Supply Chain Risk Management, written by Manmohan S Sodhi, Byung-Gak Son and Christopher S Tang, presents a study of this diversity from the perspectives of operations and supply chain management scholars. In their study they identify three gaps: a definition gap, a process gap and a methodology gap, and they suggest how these gaps can be closed.

Supply Chain Risk Management is a area that has seen a significant growth in recent years. However, there is diverse perception of research in supply chain risk because these researchers have approached this area from different domains. A recent article on Researchers’ Perspectives on Supply Chain Risk Management, written by Manmohan S Sodhi, Byung-Gak Son and Christopher S Tang, presents a study of this diversity from the perspectives of operations and supply chain management scholars. In their study they identify three gaps: a definition gap, a process gap and a methodology gap, and they suggest how these gaps can be closed.

The three gaps

Because SCRM is still a nascent area, so the authors, most researchers in this area tend to come from different more established areas. However, this diversity affects collaboration with other researchers […] and it can also hamper research engagement with industry. Essentially, there are three areas where researchers disagree most:

(1) a definition gap—there is no clear consensus on the definition of SCRM (because some limit the scope of SCRM to rare but large impact events while others believe that SCRM is about demand-supply uncertainties);

(2) a process gap—there is lack of research on an important aspect of the risk management process, namely, the response to supply chain risk incidents; and

(3) a methodology gap—there is shortage of empirical research in the area of SCRM.

This is creating three gaps that need to be closed for supply chain risk research to achieve some common ground.

SCRM Literature Review

According to the authors, a useful first step in learning more about these gaps is to characterize the diversity in scope in supply chain risk research methods among researchers. So they do, and they come up with this selected list of articles (in chronological order):

- Jüttner et al. (2003)

Based on sources: environmental risk sources, network risk sources, and organizational risk sources - Spekman and Davis (2004)

Six dimensions of supply chain as risk sources, (1) inbound supply, (2) information flow, (3) financial flow, (4) the security of a firm’s internal information system, (5) relationship with partners, and (6) corporate social responsibility - Cavinato (2004)

Based on five subchains/networks as risk sources, (1) physical, (2) financial, (3) informational, (4) relational, and (5) innovational - Chopra and Sodhi (2004)

Categorize supply chain risks at a high level as disruptions or delays. These risks pertain to (1) systems, (2) forecast, (3) intellectual property, (4) receivable, (5) inventory and (6) capacity risk - Christopher and Peck (2004)

Categorize supply chain risks as (1) process, (2) control, (3) demand, (4) supply, and (5) environmental - Kleindorfer and Saad (2005)

Based on the sources and vulnerabilities of risks, (1) operational contingencies, (2) natural hazards, and (3) terrorism and political instability - Bogataj and Bogataj (2007)

Categorize supply chain risks as (1) supply risks; (2) process risks; (3) demand risks; and (4) control risks - Sodhi and Lee (2007)

Categorize supply chain risks in the consumer electronics industry broadly as those requiring strategic decisions and those requiring operational decisions, in three categories: (1) supply, (2) demand, and (3) contextual risks - Tang and Tomlin (2008)

Categorize supply chain risks as (1) supply, (2) process, and (3) demand risks, (4) intellectual property risks, (5) behavioral risks, and (6) political/social risks - Manuj and Mentzer (2008a)

Categorize supply chain risks as (1) supply, (2) operations, (3) demand, and (4) other risks including security and currency risks, See - Manuj and Mentzer (2008b)

for another categorization: (1) supply, (2) operational, (3) demand, (4) security, (5) macro, (6) policy, (7) competitive, and (8) resource risks - Oke and Gopalakrishnan (2009)

Consider low-impact high-frequency and high-impact low-frequency risks in three major categories: (1) supply, (2) demand, and miscellaneous risks in the retail sector - Rao and Goldsby (2009)

Categorize supply chain risks as (1) framework and (2) problem specific, and (3) decision making risk

Many of these articles have been reviewed on this blog (see links), some I know of, but hadn’t had the chance to review, while some are completely unknown to me, adding yet more papers to my already 2-foot high pile of “to be reviewed”-papers on my desk :(

The authors come up with even more articles and

classified the existing SCRM literature according to four key elements for managing supply chain risks: (1) risk identification; (2) risk assessment; (3) risk mitigation; and (4) responsiveness to risk incidents, the last one subdivided into responsiveness to (a) operational risks (frequent risk events stemming from inherent supply-demand uncertainty); and (b) catastrophic risks

I think this is an excellent classification scheme, as it follows the standard risk management procedures laid out in ISO73.

What is supply chain risk management?

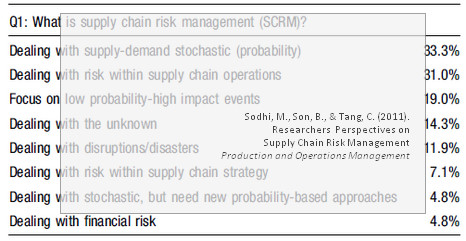

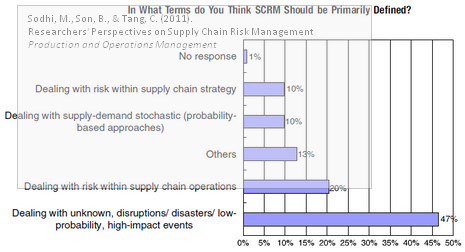

Because the literature review indicated that there is much diversity in the scope including in definition of SCRM, the authors decided to investigate this further and conducted a survey on the definition of supply chain risk and of SCRM, asking the following main questions, with subsequent follow-up questions.

Q1 What is supply chain risk management (SCRM)?

Q2 How is SCRM different from supply chain management?

Q3 What is the link between SCRM and Enterprise Risk Management (ERM)?

Interestingly, the answer for the first question are somewhat divergent, see below:

When asked what SCRM is, disruptions and disasters rank low on the list.

When asked what SCRM should primarily be defined as, disruptions and disasters come up top of the list. Personally, I am not sure which is better; what do you think?

Supply Chain Risk Management goes where?

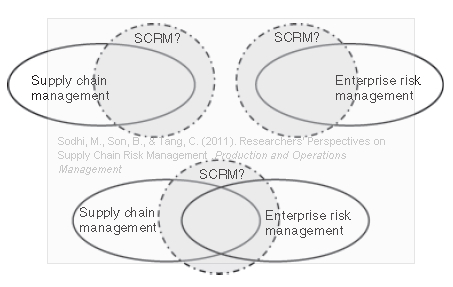

The authors also asked where supply chain risk management should be placed in relation to supply chain management and in relation to enterprise risk management, resulting in the following figures:

I think they got it right, because SCRM cannot be decoupled from SCM, nor can it be decoupled from ERM. In my opinion.

Conclusion

This paper should be required reading for any supply chain risk researcher. Not only does it list the most important works in supply chain risk management research, it classifies them in accordance with established risk management norms and it also lays the groundwork for future research into supply chain risk, by asking the research community itself where it thinks supply chain risk should place itself and where it should be headed, thus building rapport with those most likely to follow suit.

Reference

Sodhi, M., Son, B., & Tang, C. (2012). Researchers’ Perspectives on Supply Chain Risk Management Production and Operations Management, 21 (1), 1-13 DOI: 10.1111/j.1937-5956.2011.01251.x

Author links

- city.ac.uk: Manmohan S Sodhi

- city.ac.uk: Byung-Gak Son

- ucla.edu: Christopher S Tang

Related posts

- husdal.com: Current gaps in supply chain risk research