Supply Chain Risk Management has emerged as an important source of competitive advantage and an effective method of reducing vulnerability in a supply chain. One vulnerability or risk that is often overlooked are product design changes to an already existing manufacturing process. That is the topic of a recent article by Yong Lin and Li Zhou titled The impacts of product design on supply chain risk: a case study. This a highly recommendable article for anyone thinking of studying risk management in supply chains.

Supply Chain Risk Management has emerged as an important source of competitive advantage and an effective method of reducing vulnerability in a supply chain. One vulnerability or risk that is often overlooked are product design changes to an already existing manufacturing process. That is the topic of a recent article by Yong Lin and Li Zhou titled The impacts of product design on supply chain risk: a case study. This a highly recommendable article for anyone thinking of studying risk management in supply chains.

More than meets the eye

To me, the major point of this article is not the case study of a Chinese manufacturer of Special Purpose Vehicles, but a cause and effect diagram showing how internal and external risk affect all processes in the supply chain. Even more useful is a set of nine criteria used for assessing the trustworthiness of a case study. Not to mention the 80 or so references in the bibliography, where – as always – I didn’t find articles that I thought they would have cited, but more importantly, I found lots of articles I had not heard of before. Add to that a very detailed description of how the case study was undertaken and the lessons learned from it, this article is nothing less than a cookbook in supply chain risk management case studies.

Cause and effect

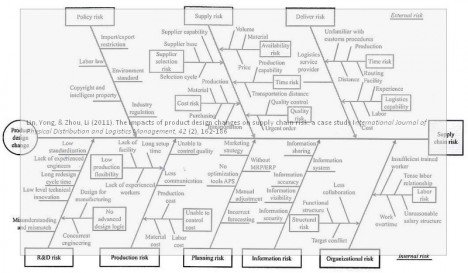

One very illustrative figure in the article is a cause and effect diagram showing internal and external supply chain risk in a product design change perspective.

Although based on this particular case study, in my opinion this diagram is generally applicable to almost any manufacturing supply chain.

Internal risks are related to:

- R&D risk: The inability to quickly redesign the product to meet customer’s requirements for design change

- Production risk: The inability to quickly and efficiently produce the product with customer’s changed design

- Planning risk: The inability to maintain stable and consistent planning production planning and scheduling

- Information risk: The inability to share information among different supply chain roles and make it accurate, secure and visible across the entire supply chain

- Organizational risk: The inability to adjust the organization structure and operational processes to match the dynamic characteristics of customer demand

External risks are related to

- Policy risk: The inability to meet industry and government regulations, trade rules and legal standards

- Supply risk: The inability to guarantee supply availability, timeliness, cost and quality

- Delivery risk: The inability to deliver on time and to guarantee the logistic capability

Trustworthiness criteria

A very interesting selling point of this article is the use of trustworthiness criteria and how the case study meets these:

- Credibility: Extent to which the results appear to be acceptable representations of the data

- Transferability: Extent to which the findings from one study in one context will apply to other contexts

- Dependability: Extent to which the findings are unique to time and place; the stability or consistency of explanations

- Confirmability: Extent to which interpretations are a result of the participants and the phenomenon as opposed to researcher biases

- Integrity: Extent to which interpretations are influenced by misinformation or evasion of participants

- Fit: Extent to which findings fit with the substantive area under investigation

- Understanding: Extent to which participants buy into results as possible representations of their worlds

- Generality: Extent to which findings discover multiple aspects of the phenomenon

- Control: Extent to which organizations can influence aspects of the theory

I find this an incredibly useful set of criteria, perhaps a few too many, but nonetheless, I think these are the critera every case study should be judged against.

Critique

There is only one “negative” point to be made about this article: It’s a bit on the long and detailed side, too detailed perhaps in its description of the case study. However, I don’t see where it could have been shortened. Having said that, the positive takeaways from this article which I already mentioned in the beginning more than outweigh the fact that it does take a while to fully read this article. Kudos on an job well done.

Reference

Lin, Yong, & Zhou, Li (2011). The impacts of product design changes on supply chain risk: a case study International Journal of Physical Distribution and Logistics Management, 42 (2), 162-186 DOI:10.1108/09600031111118549

Author links

Related posts

- husdal.com: Product design and supply chain risk