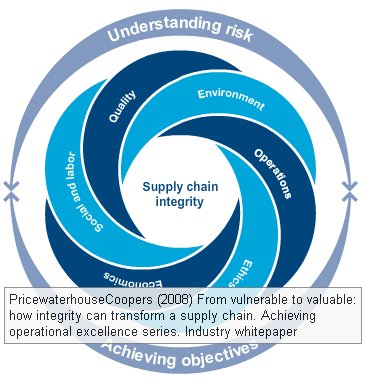

More than a year old now, but still holding not so few words of wisdom is the Pricewaterhouse Coopers report on supply chain integrity: From vulnerable to valuable. Their analysis shows that moving away from the typical business mindset of supply chain improvements only in terms of cost reductions is well worth the effort. Companies must invest in enhancing the integrity of their supply chains, in a manner which balances operational objectives with reputational risks. This requires developing “leading risk indicators” in addition to the typical Key Performance Indicators, in order to measure supply chain performance.

More than a year old now, but still holding not so few words of wisdom is the Pricewaterhouse Coopers report on supply chain integrity: From vulnerable to valuable. Their analysis shows that moving away from the typical business mindset of supply chain improvements only in terms of cost reductions is well worth the effort. Companies must invest in enhancing the integrity of their supply chains, in a manner which balances operational objectives with reputational risks. This requires developing “leading risk indicators” in addition to the typical Key Performance Indicators, in order to measure supply chain performance.

Supply chain disruptions are costly

Companies do not recover quickly from a supply chain disruption. In the PWC analysis, two-thirds of affected companies were lagging their peers in stock price performance a year after the disruption. Sheffi’s disruption profile, which has been mentioned time and again on this blog, holds true: A company suffering from a supply chain disruption will not get back to business as usual for a long time, and will sustain a long-term effect. As the Swedish mobile manufacturer Ericsson experienced in 2001, an ill-handled supply chain disruption can in fact lead to business discontinuity.

Supply chain integrity

A company must always balance objectives and risk, so says PWC in their report. They call it achieving supply chain integrity.

Supply chain integrity must encompass both operational and reputational dimensions. Operational integrity refers to the ability of the supply chain to meet objectives for quality, productivity, and financial performance. Reputational integrity refers to the ability of the supply chain to protect and enhance the brand, respond to customer and investor concerns, and comply with the growing burden of legislation.

On the operational side:

- Product quality assurance and failure remediation

- Operations and processes

- Economic transactions and contractual agreements

On the reputational side:

On the reputational side:

- Social and labor practices and standards

- Environmental practices and standards

- Ethical practices and standards

Disruptions and quality control issues are often caused not by a single factor, but by the convergence of many, and it is not always easy to distinguish between operational and reputational reasons for supply chain disruptions. However, in the mind of the public, everything is reputational.

Words of wisdom

The report is specked with examples and supply chain cases from the business world, showing the good and the not so good handlings of supply chain disruptions, and what indicators that some companies have developed to measure their supply chain integrity. It’s well worth a read, even from an academic point of view.

Reference

PricewaterhouseCooper (2008) From valuable to vulnerable: how integrity can transform a supply chain. Achieving operational excellence series. Industry whitepaper.

Download

- pwc.com: From vulnerable to valuable

Related

- husdal.com: Investing in supply chain security – reaping collateral benefits

- husdal.com: Enterprise wide risk management