How does a traditional supply chain compare to a vendor managed inventory supply chain when it comes to performance during disruptions? In her 2005 paper, The impact of transportation disruptions on supply chain performance, Martha Wilson found out, not surprisingly, that vendor managed inventory (VMI) fares better than the traditional retail managed inventory, even when looking at the whole supply chain: Raw Material Supplier – Tier 2 Supplier – Tier 1 Supplier – Warehouse – Retailer – Customer.

How does a traditional supply chain compare to a vendor managed inventory supply chain when it comes to performance during disruptions? In her 2005 paper, The impact of transportation disruptions on supply chain performance, Martha Wilson found out, not surprisingly, that vendor managed inventory (VMI) fares better than the traditional retail managed inventory, even when looking at the whole supply chain: Raw Material Supplier – Tier 2 Supplier – Tier 1 Supplier – Warehouse – Retailer – Customer.

The model

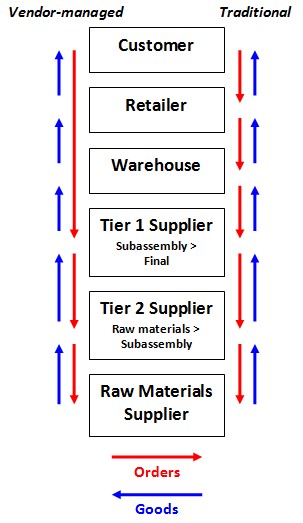

The model used in this simulation is traditional 5-echelon supply chain:

- Customer

- Retailer

- Warehouse

- Tier 1 Supplier (Subassembly > Final)

- Tier 2 Supplier (Raw Materials > Subassembly)

- Raw Material Supplier

In the traditional supply chain setup the orders flows from top to bottom, and the goods flow from bottom to top.

In a vendor managed inventory setup, customer demand numbers are passed directly to the tier 1 supplier, who then ships to the warehouse for distribution by the retailer, while sending backorders to the tier 2 supplier, according to customer demand.

Four scenarios

How does this different setup impact transportation disruptions between the four possible types of disruption: retailer-warehouse, warehouse-tier1, tier1-tier2, tier2-raw materials?

Four parameters

Four parameters are chosen as to determine performance measures:

- Retail Inventory

- Warehouse inventory

- Subassembly goods in transit

- Raw materials in transit

The performance measures are

- Unfilled retail customer orders

- Maximum number of goods in transit

- Maxiumum inventory level

- Average inventory level

These measures are then investigated in relation to the four scenarios.

Results

All scenario results are clearly displayed in separate diagrams and tables, some of which I summarized in the garph left here. It is clear that the different disruptions have different impacts throughout the supply chain.

Click image for larger version

However, a VMI setup has less impact, particular at the warehouse and retailer level, indicating that a disruption here is better served by a VMI setup than the traditional setup.

Critique

The simulation does have some constraints: 1) The models are run for 600 days with a 10-day disruption occurring at day 200. Hence, this is only one of many possible scenarios. 2) The model assumes a straightforward 5-echelon supply chain with no complex or interlinked structures. Thus, it oversimplifies, but it does give a picture or an idea of what happens where and can be an excellent starting point for further investigations.

Conclusion

Initially I posed the question Less supply chain disruptions with vendor managed inventory? The correct question should have been Less impact of supply chain disruptions with vendor managed inventory? Given the constraints and simplifications of this simulation, the answer to that question is certainly yes.

References

WILSON, M. (2007). The impact of transportation disruptions on supply chain performance Transportation Research Part E: Logistics and Transportation Review, 43 (4), 295-320 DOI: 10.1016/j.tre.2005.09.008

Author link

- csus.edu: Martha Wilson

Related

- husdal.com: Supply chains and barcodes