In my previous post on Ericsson versus Nokia – the now classic case of supply chain disruption I mentioned that Ericsson’s and Nokia’s different handling of the same supply chain disruption has become somewhat of a textbook case of how ill-handled disruptions can make or break a company’s existence. Here it is again, as the introduction to an article on tailored risk management by Sunil Chopra and ManMohan S. Sodhi from 2004. The essence of the article is that by understanding the variety and interconnectedness of supply chain risks, managers can tailor balanced and effective risk-reduction strategies for their companies.

In my previous post on Ericsson versus Nokia – the now classic case of supply chain disruption I mentioned that Ericsson’s and Nokia’s different handling of the same supply chain disruption has become somewhat of a textbook case of how ill-handled disruptions can make or break a company’s existence. Here it is again, as the introduction to an article on tailored risk management by Sunil Chopra and ManMohan S. Sodhi from 2004. The essence of the article is that by understanding the variety and interconnectedness of supply chain risks, managers can tailor balanced and effective risk-reduction strategies for their companies.

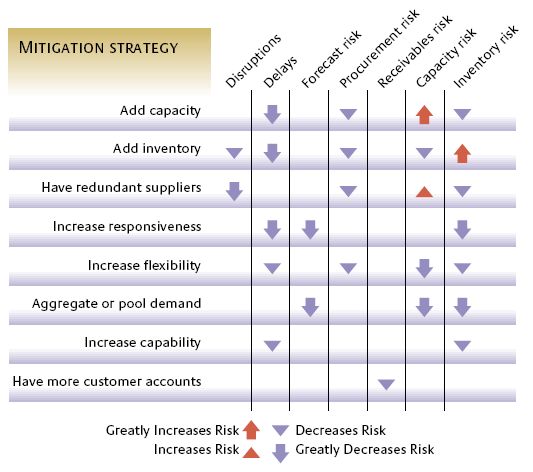

Mitigation strategies

The first key message of Chopra and Sodhi is that some mitigation strategies may actually increase risk in some business areas, rather than reduce it, see figure left. The figure shows how different strategies affect different areas of the supply chain differently. Major risks that need special attention are: Disruptions, Delays, Forecast risk, Procurement risk, Receivables risk, Capacity risk and Inventory risk. Some of the strategies to address these risk are: Add capacity, Add inventory, Have redundant suppliers, Increase responsiveness, Increase flexibility, Aggregate or pool demand, Increase capability, Have more customer accounts. The matrix shows how risks and mitigations measures are interlinked and affect each other.

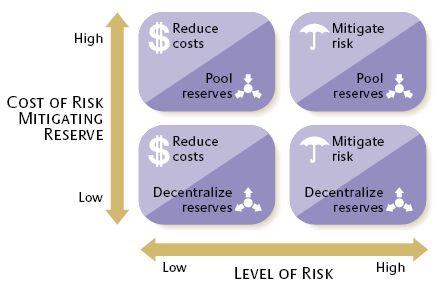

Rules of thumb for tailored risk management

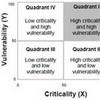

The second key message of Chopra and Sodhi is that the cost of mitigating or building up a reserve must be balanced against the level of risk, see figure left. Three time-tested approaches that can be used are: Pooling inventory, Creating common components across products and Postponing or delaying the last stage of production. In addition, companies can minimize inventory by working with highly responsive supplier, especially for high-value products with short life cycles.

Reference

Chopra, S., & Sodhi, M.S. (2004). Managing Risk to Avoid Supply-Chain Breakdown MIT Sloan Management Review, 46 (1), 53-61

Author Links

- kellog.northwestern.edu: Sunil Chopra

- cass.city.ac.uk: ManMohan S Sodhi

Related

- husdal.com: Global Supply Chain Risk Management